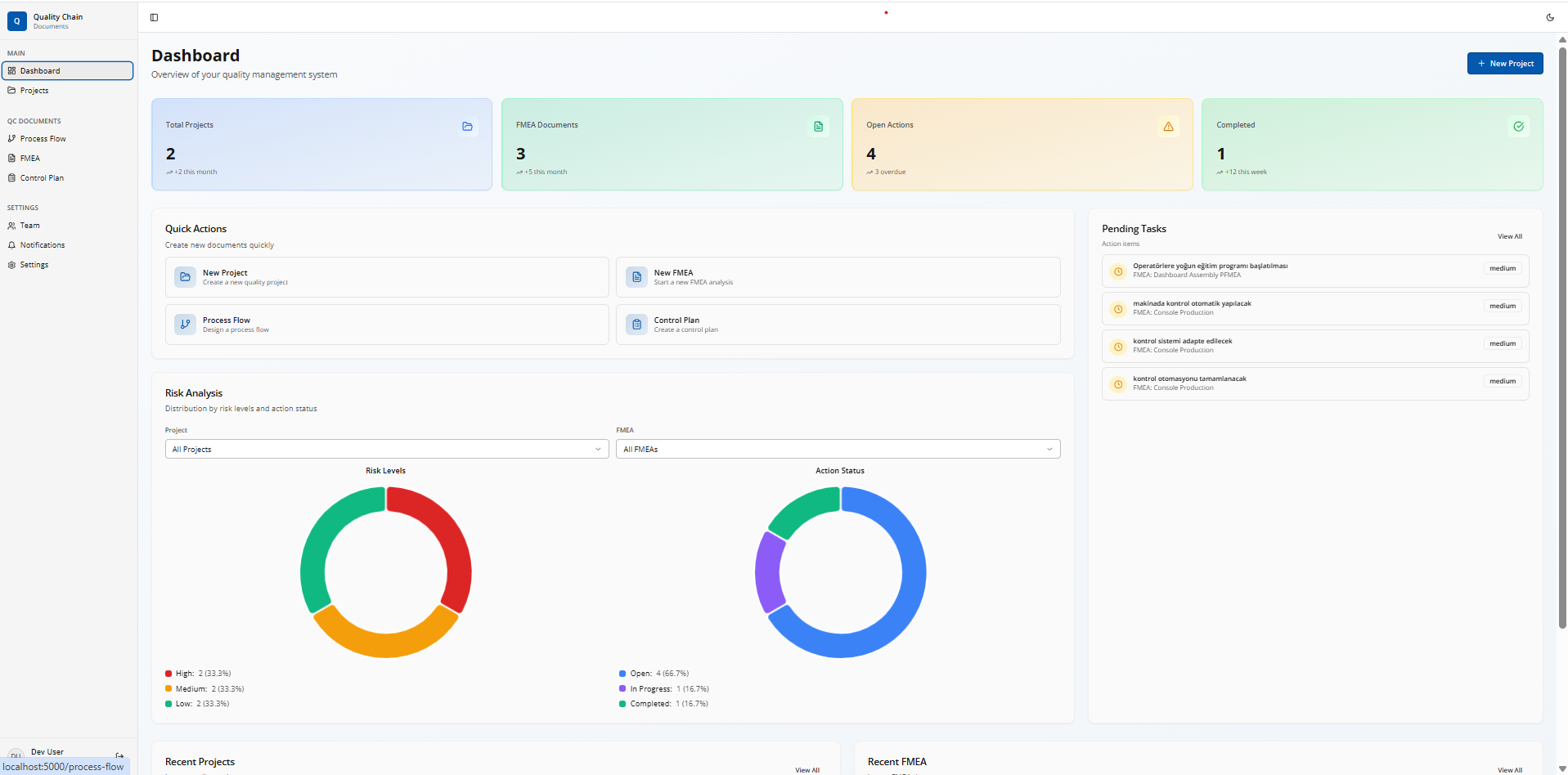

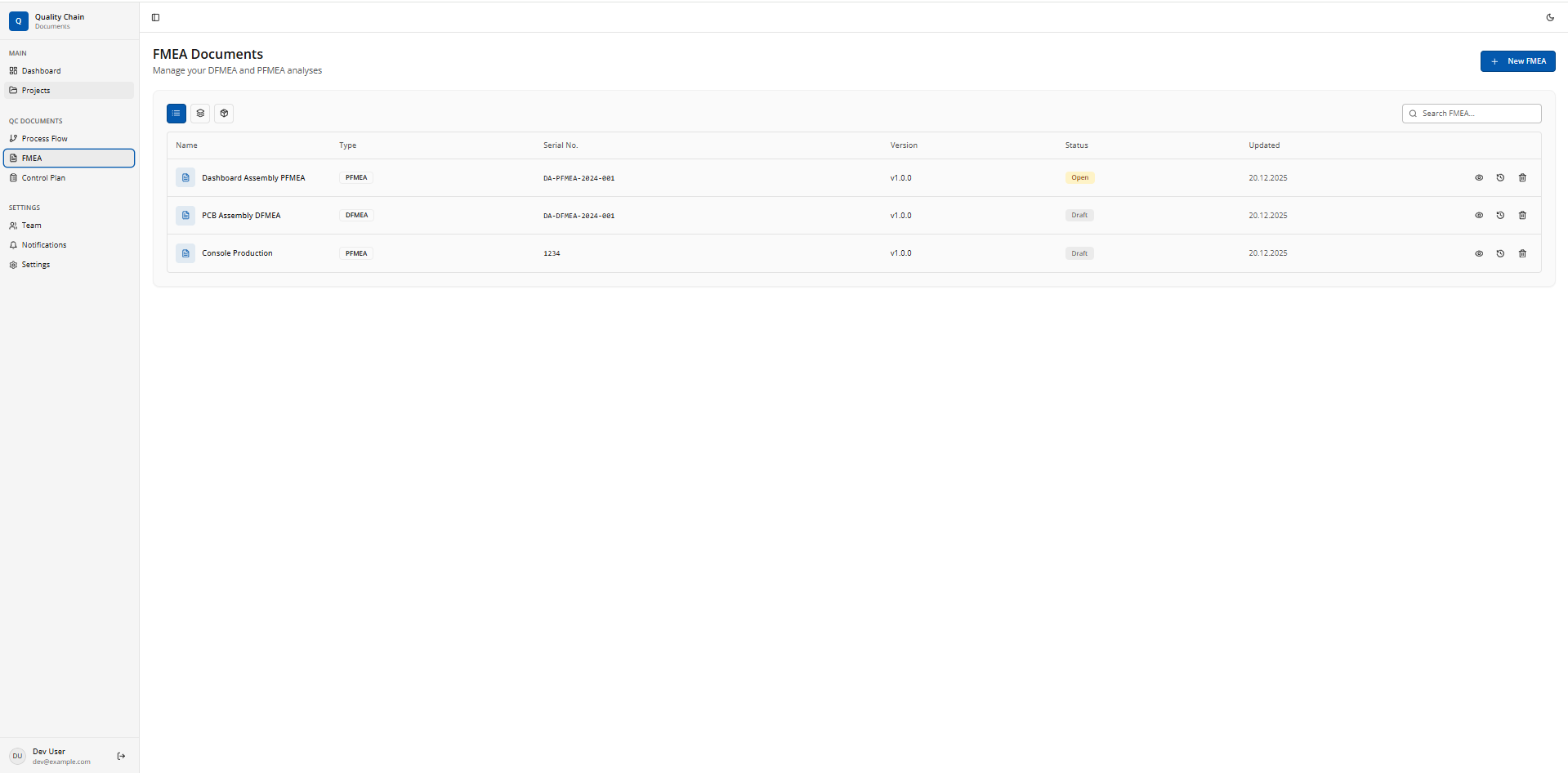

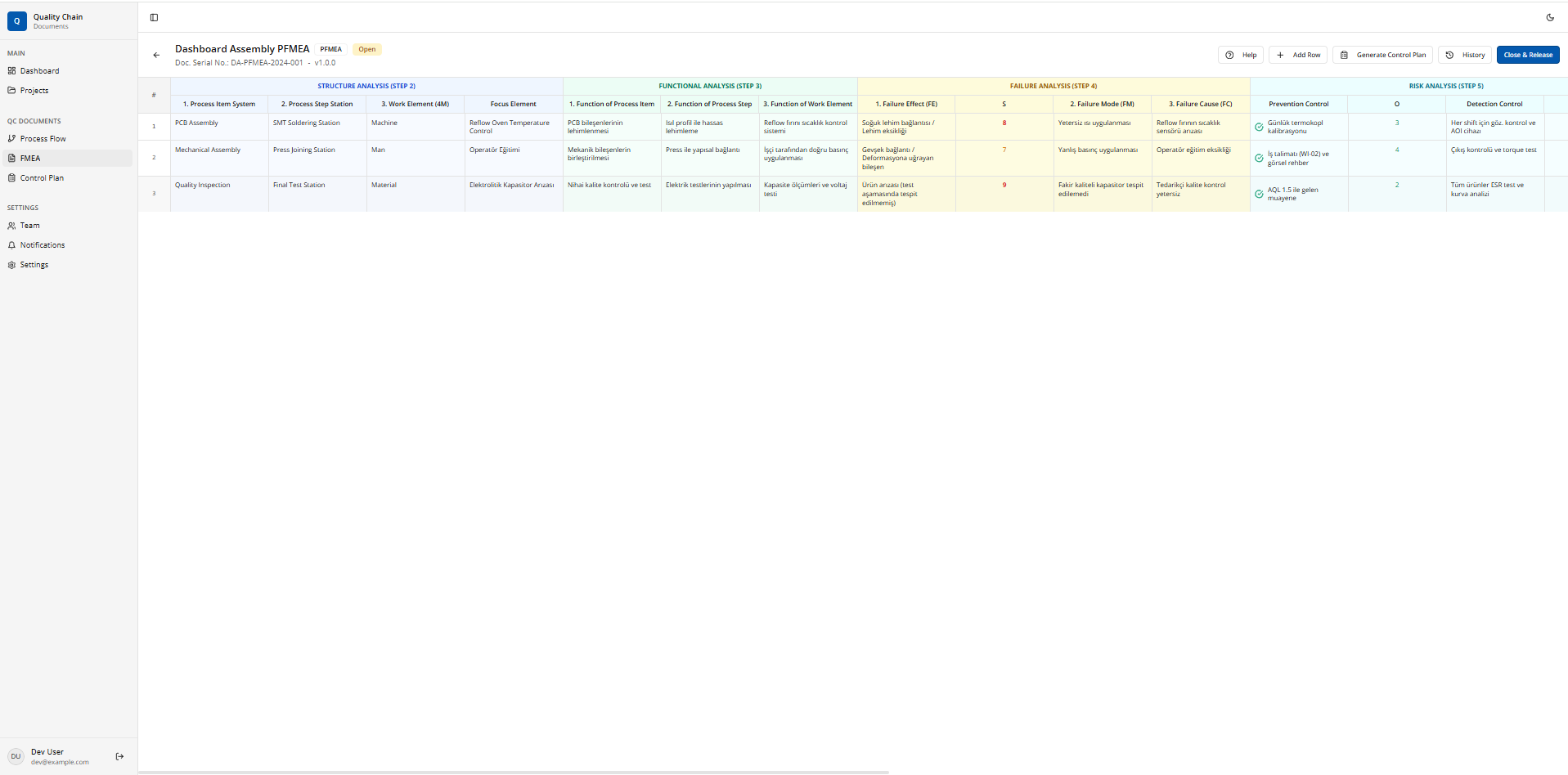

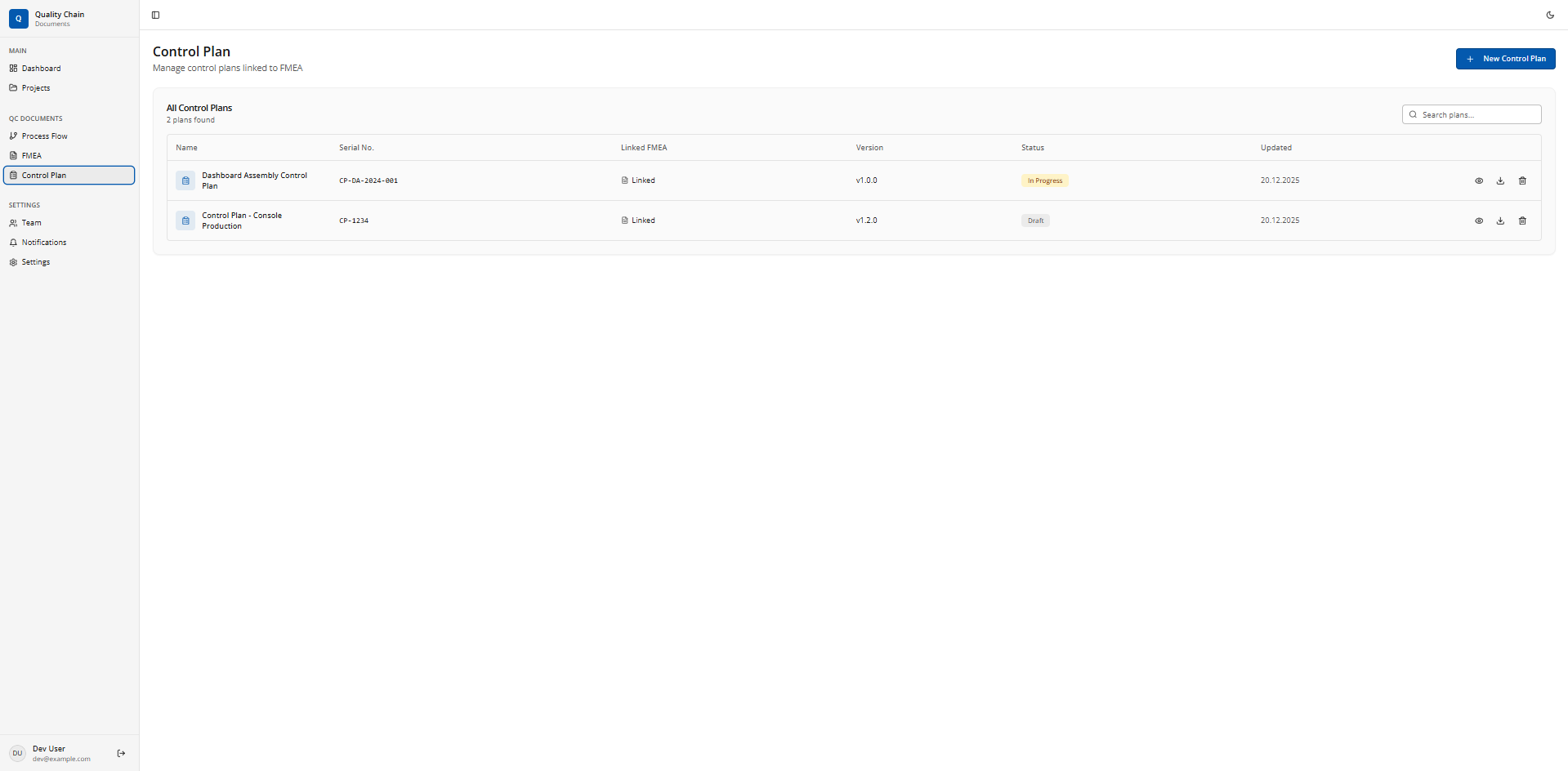

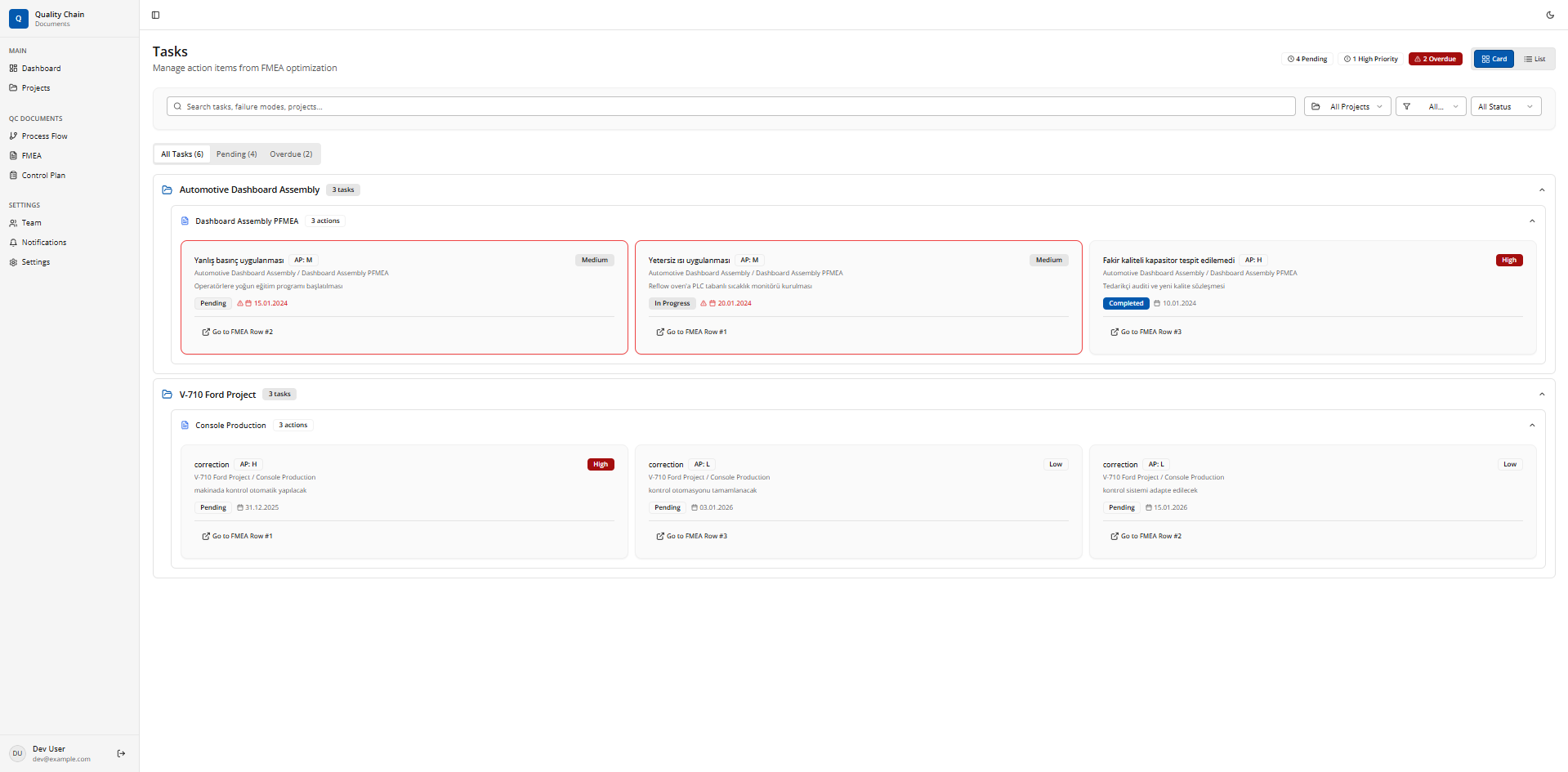

FMEA Control Plan Software

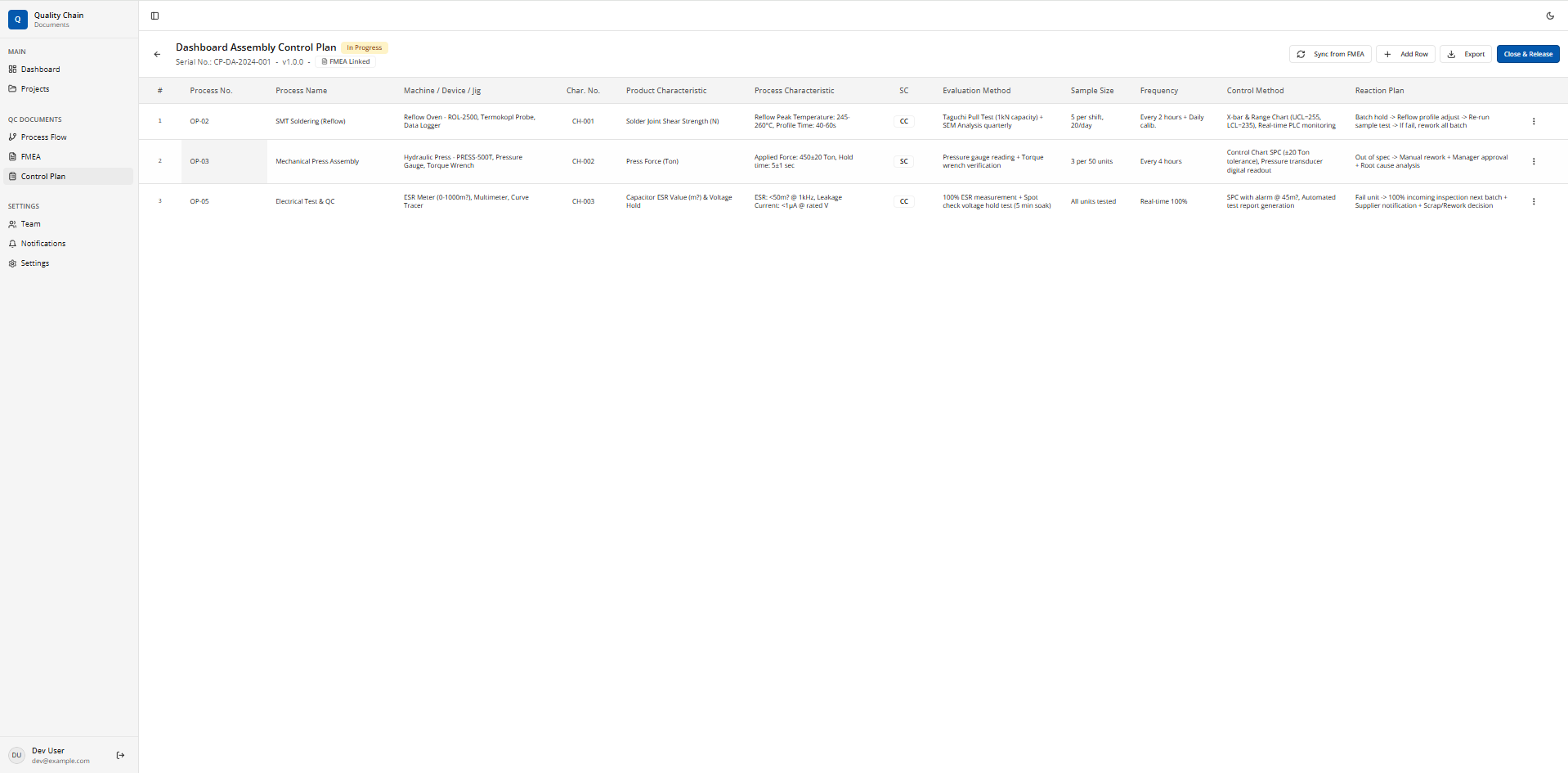

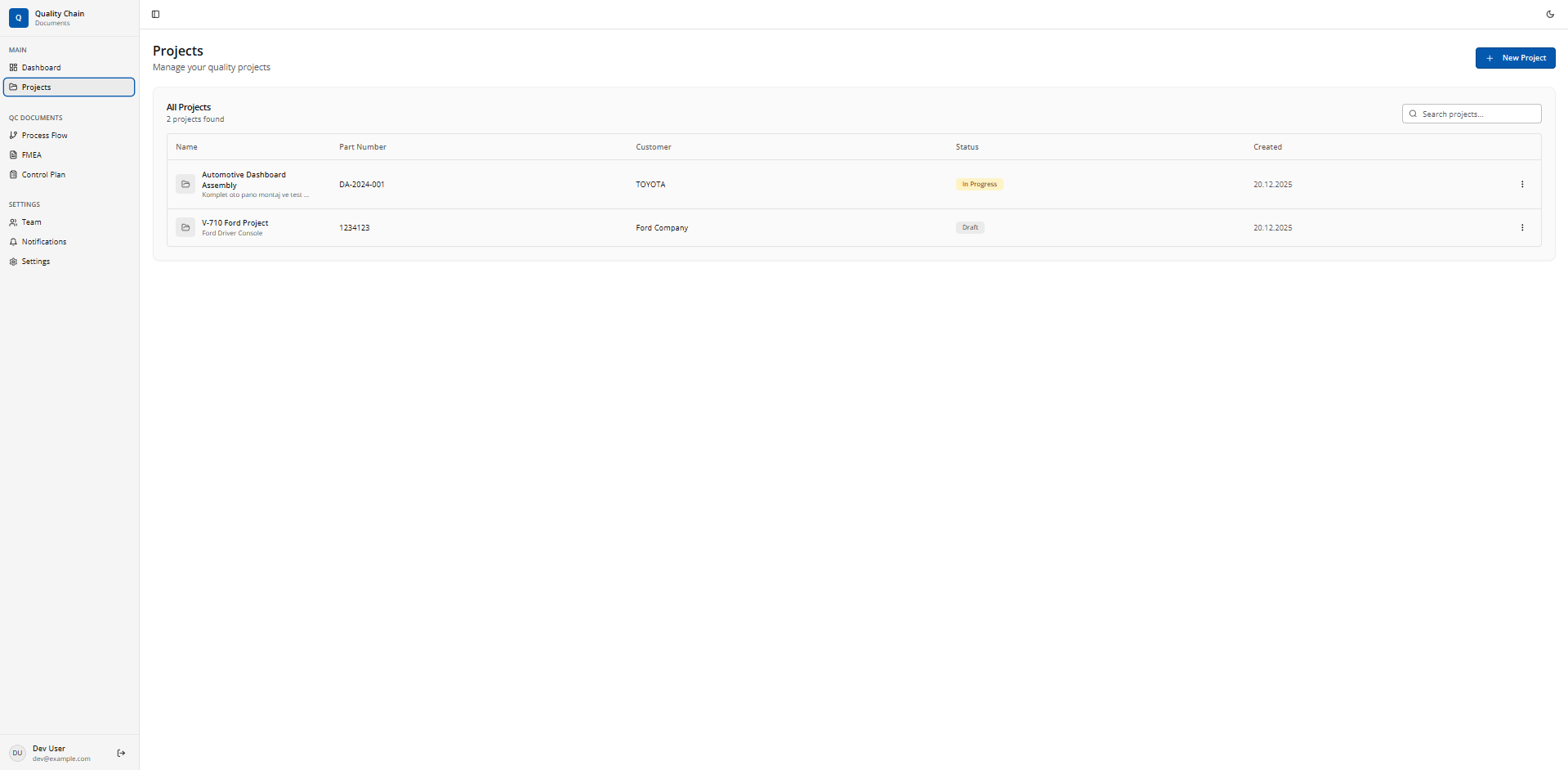

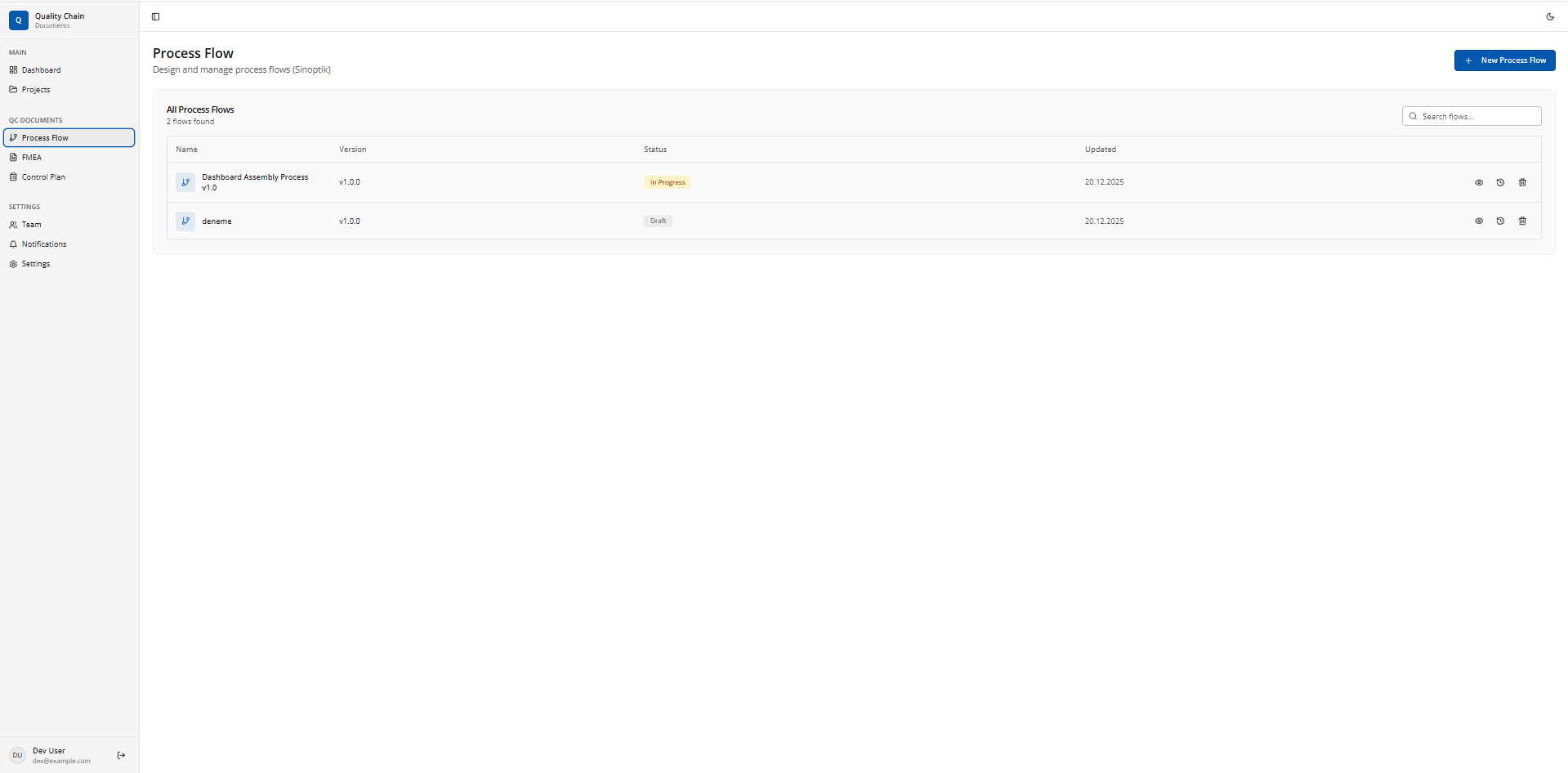

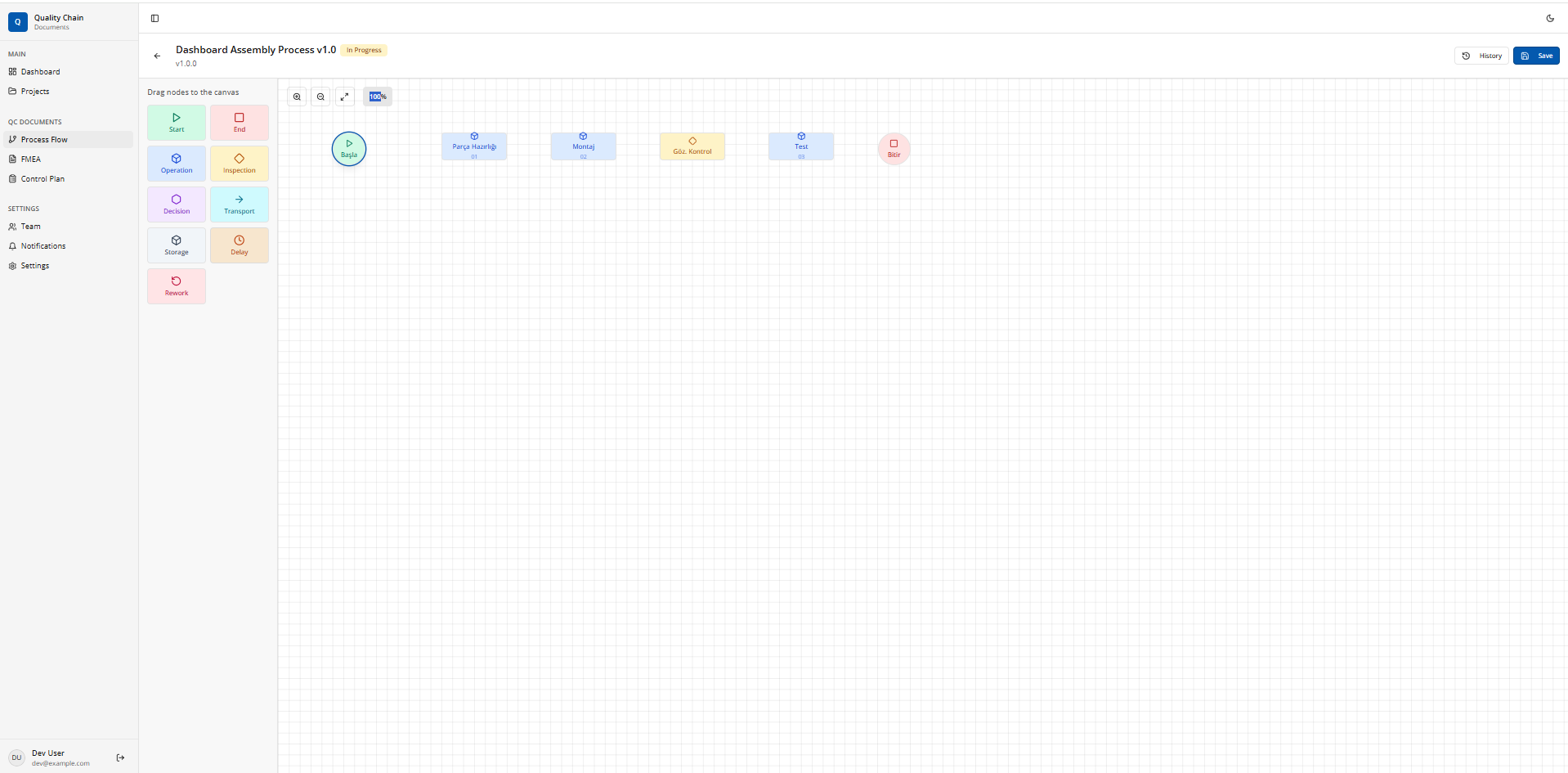

Comprehensive Failure Mode and Effects Analysis (FMEA) and Control Plan management solution for manufacturing quality assurance. Systematically identify potential failure modes, assess their impact, and implement preventive controls to eliminate risks before they become quality issues.